"Do not own anything you are not prepared to repair.” - Wendell Berry

Elapsed time

1d 9h 8m

Avg. speed

2.2kts

Distance

74.2nm

Moving time

1d 9h 8m

Max. speed

-- kts

Philadelphia, Philadelphia County, Pennsylvania, USA

Feb 29, 2024 - Mar 1, 2024

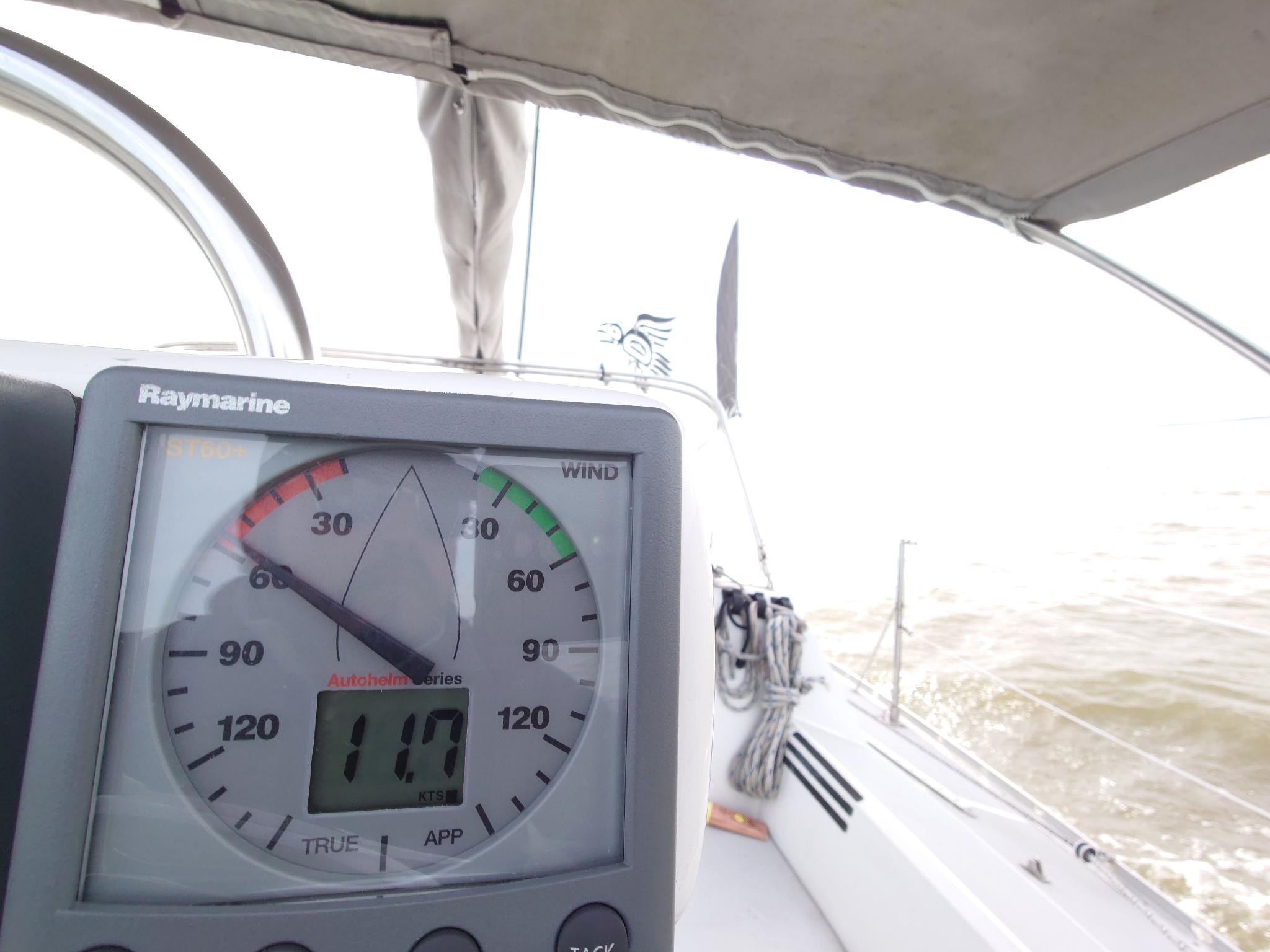

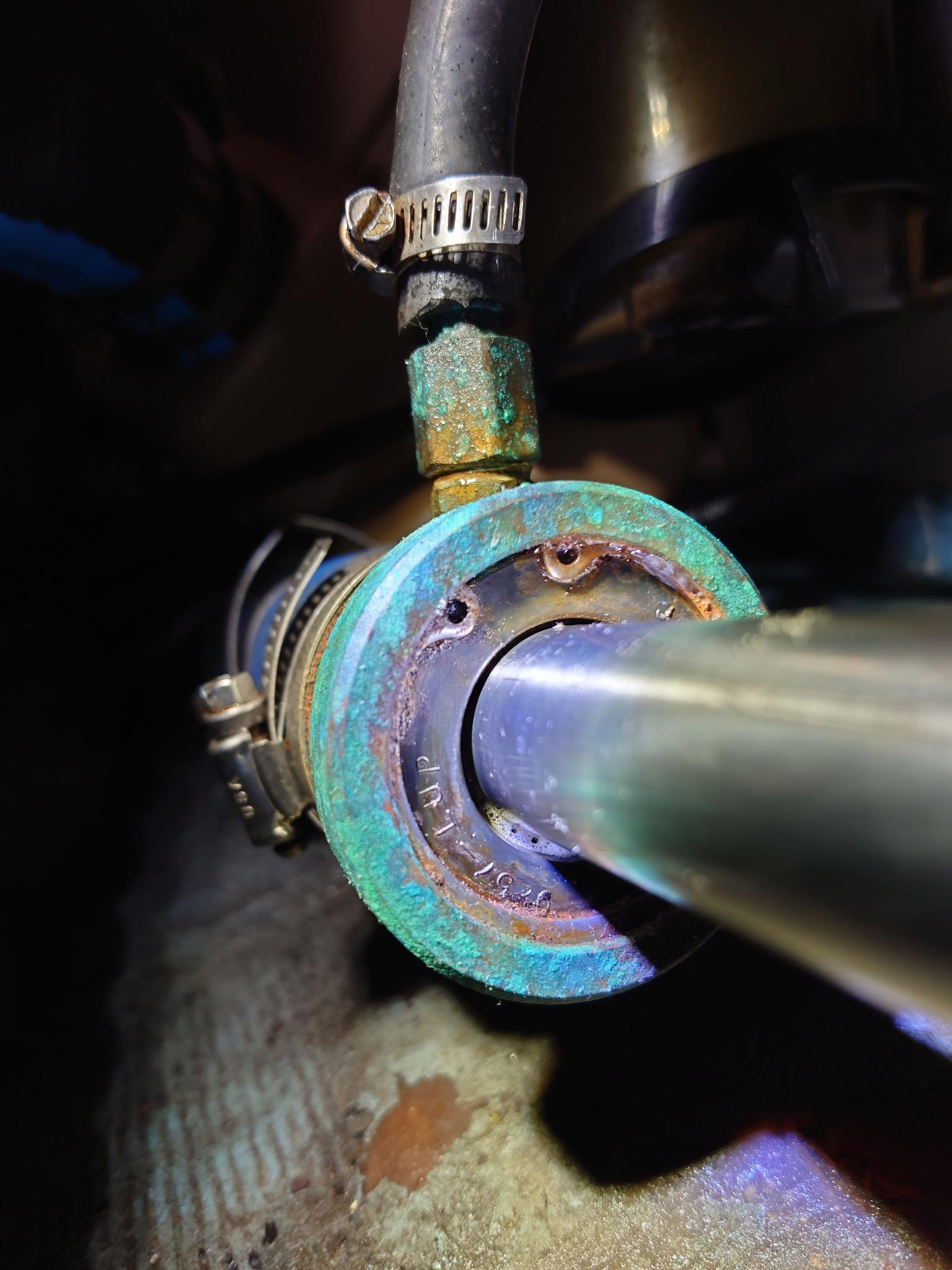

Repair log#4 – Worton Creek Haul-Out After the trip home in the fall, I started searching for a new marina that could haul me out. The Cutless bearing had started making more and more noise as the days passed, and the dripless shaft seal had developed a persistent leak. Nothing catastrophic... but it all needed doing. Much like most navigating local knowledge is important so I asked around and landed on Worton Creek marina. The plan was straightforward. Pull the shaft. Replace the Cutless. Swap the shaft seal. Realign the engine. In theory, this was the clean-up job, the follow-through. The correction of problems that had been hidden by other problems. I didn’t do most of the work myself this time. I should have. The mechanics at Worton weren’t careless. They did a better job than some. The shaft had been riding the bottom of the log, literally rubbing, and they corrected that. Got it centered. Installed the new bearing. Replaced the seal. But they forced the shaft into the coupling with a hammer. Missed the bolt detents. Tightened it down like it was done right. It wasn’t. The dripless never sealed properly under way. Just a slow, steady leak... enough to trigger the bilge pump every hour or so. The new Cutless started rattling again after a few months. And a few days after getting home to Philadelphia, the shaft backed out of the coupler completely. I was reversing into a slip at Penn’s Landing when it happened. I suddenly lost all propulsion. I managed to coax the unpowered hull into the slip. Let some guests off who had joined me for a quick trip down the river. I went below to check the shift cable, but the shaft and coupler were moving independently. I tried to pull the shaft forward. It wouldn’t budge. Slid it aft instead... and saw faint marks where the lock bolts had been tightened. A few inches further, I found the detents. That’s when it clicked. The shaft had been hammered in too far. The bolts had clamped into bare shaft, not the indentations meant to hold them. No matter what I tried, the shaft wouldn’t slide forward. I tried tools. Tension. Begging. Nothing. Just sweat and frustration. I called Worton Creek. The maintenance manager apologized, but said they couldn’t help unless I brought the boat back. That wasn’t happening. My plan had already started to form. I removed the shaft-side coupler plate and mounted it directly on the shaft, measuring and marking carefully to make sure it was set to the proper depth. Then I lined it up with the transmission-side plate, ran threaded rod through both halves, and slowly pulled the two together. Turn by turn, the shaft slid forward... pulled into place by pressure and patience. Once drawn back together it was a relatively simple job to bolt the two halves of the plate together and the job was done. Don't get me wrong... there was plenty of sweating, swearing, busting of knuckles, and frustration... but overall nothing surprising that I would have to come up with solutions for. Simetimes trust can only get you so far. I trusted that paying a pro meant the job would stay fixed. But First Light keeps teaching the same lesson... no one’s going to care about your boat like you do. And “almost right” doesn’t count when you’re backing into a slip and everything comes undone.

Boat & Crew

First Light

O'Day, 322